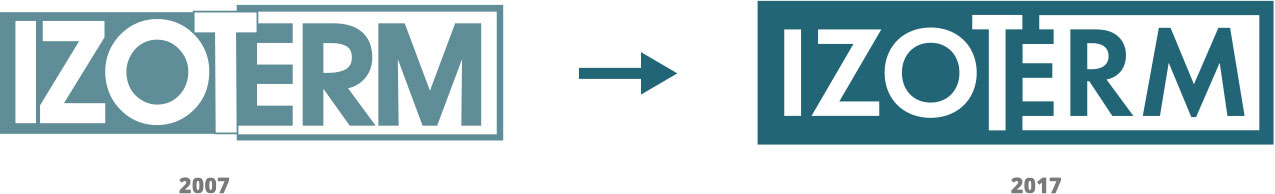

The IZOTERM plant is the first of the factories in Kazakhstan that produces modern & nbsp; heat-insulating materials based on basalt fiber, using European equipment & nbsp; Slovenian concern "EUROVEK". The company has two plants for the production of mineral & nbsp; heaters. & Nbsp; In 2007, a plant was put into operation in Ust-Kamenogorsk, the village of Gluboky. & Nbsp; In 2017, due to the great demand for products, the company expanded and launched a second & nbsp; plant , located in Temirtau, equipped with the latest equipment, which allows & nbsp; to produce the highest quality products at minimum production costs. & nbsp; The experience of the plant acquired over many years allows us to produce heat-insulating materials with an optimal price-quality ratio. Mats and slabs have high & nbsp; indicators for environmental friendliness, thermal conductivity and fire resistance, meeting & nbsp; modern requirements for thermal insulation materials.

Since 2017, the IZOTERM plant is part of the MAMYR group of companies

IZOTERM is a new generation of domestic high-quality heat and sound insulation materials based on stone wool. This is due to their widespread use in the construction, reconstruction or repair of residential buildings and industrial buildings.

Products IZOTERM has passed all the necessary tests and certification on the territory of the Republic of Kazakhstan and the Russian Federation.

• Kazakhstan plant producing modern heat-insulating materials from basalt fiber with the trade mark

IZOTERM ;

• Scope of destination: industrial and civil construction, industrial enterprises and heat power engineering;

• Investments: more than 6 billion tenge;

• Workplaces - 600 people

• Production base: Glubokoe settlement, East Kazakhstan region;

• Total area of industrial premises - 60,000 sq. M .;

• Territory - 8.9 hectares;

• Supplier of equipment and technologies: company

EUROVEK part of the TERMO concern (Slovenia), the largest producer of mineral wool products in Europe. & nbsp;

Environmentally friendly mineral wool IZOTERM consists of the finest interlocking fibers obtained by high-temperature melting of stone (gabbro-diabase). & nbsp;

Thermal insulation properties of mineral wool IZOTERM are caused by the content in it of a large number of air pores and channels up to 96% of the total volume of cotton wool, in which the thermal conductivity of air in a stationary state is very low.

Recipe for success IZOTERM - the presence of unique competitive advantages, a convenient geographical location in relation to raw material bases and main sales markets, the presence of highly qualified technical specialists trained abroad. & nbsp;

The range of products includes a wide range of positions, focused on meeting all market needs, and are ready to satisfy the most demanding customer. An effective quality control of products has been established, thanks to its own accredited laboratory and the presence of a testing and training center. & Nbsp;

The company invests great efforts in the development of production, improving equipment and constantly improving the quality of products. The use of innovative technologies in production allowed the enterprise to reach a new level in a short time, allowing it to compete with both Russian and foreign manufacturers. The production line makes it possible to take into account the preferences of each client regarding the dimensions and thicknesses of the slabs and to produce products of non-standard sizes, as well as slabs for the production of sandwich panels.

Control over the operation of the line is carried out from two command consoles

IZOTERM is a new generation of domestic high-quality heat and sound insulation materials based on stone wool, intended for civil and industrial construction.

Range IZOTERM includes heat and sound insulation boards for insulation of roofs and facades of buildings, for production with shade and roofing panels of the sandwich type, non-load-bearing insulating plates for building envelopes, as well as heat-insulating mats made of basalt fiber, laminated with foil and fiberglass.

IZOTERM on the market is high quality mineral wool products for perspective and professional construction. & nbsp;

Recipe for success IZOTERM - unique competitive advantages and dynamic development. The assortment includes positions oriented to the needs of the market, effective control of the quality of manufactured products has been established. The distribution network is efficiently functioning.